Home > Industry news

In view of this, Professor Wang Xianyou of Xiangtan University successfully prepared a double-coated hollow spherical Si@TiO2@C anode material by one-step method.

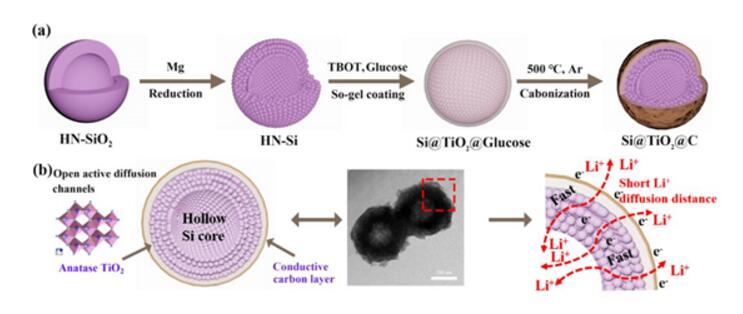

Figure 1 Schematic diagram of (a) preparation and (b) structure of Si@TiO2@C anode material

In this work, hollow Si spheres were prepared by template-free method and magnesium thermal reduction method, and then hollow spheres HN-Si were coated with butyl titanate and glucose to prepare Si@TiO2@ with rich pore structure and high stability. C negative electrode material.

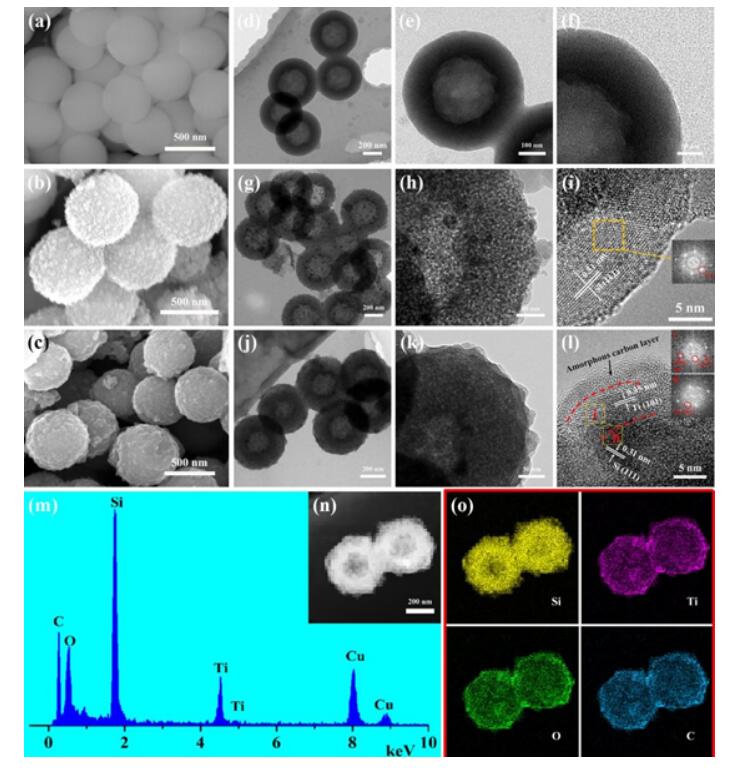

Fig. 2 Electron micrograph of SiO2(a, d-f), HN-Si(b, g-i) and Si@TiO2@C(c, j-l)

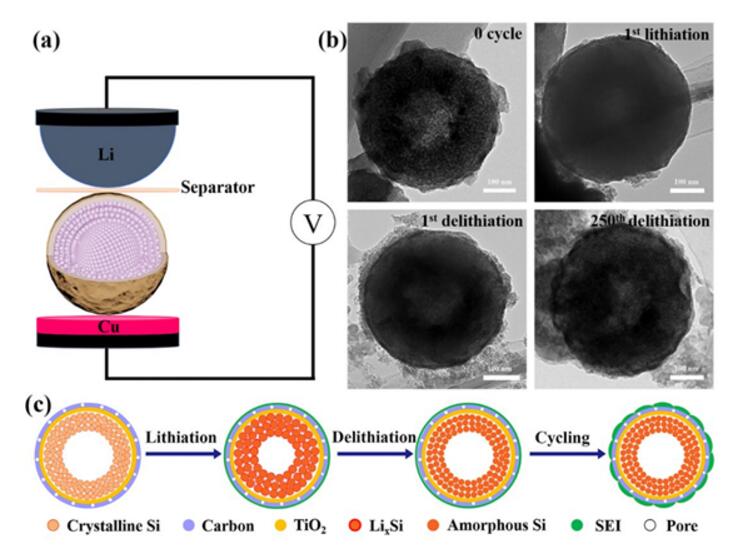

Firstly, in the process of battery charge and discharge, Si nanospheres with hollow structure can self-adjust large volume expansion; secondly, TiO2 shell can increase lithium ion transmission rate (volume expansion rate is only 4%) due to its structural advantages, and Further, the volume expansion of the Si active material is transferred to the inner cavity instead of outward; finally, the outer C layer further improves the electrical conductivity and structural stability of the composite.

The results indicate that the traditional single-layer cladding strategy cannot meet the structural stability requirements of electrode materials in the face of the huge volume expansion effect of Si anode materials, and this new double-cladding-hollow strategy It can effectively improve the volume expansion effect of silicon and improve its conductivity.

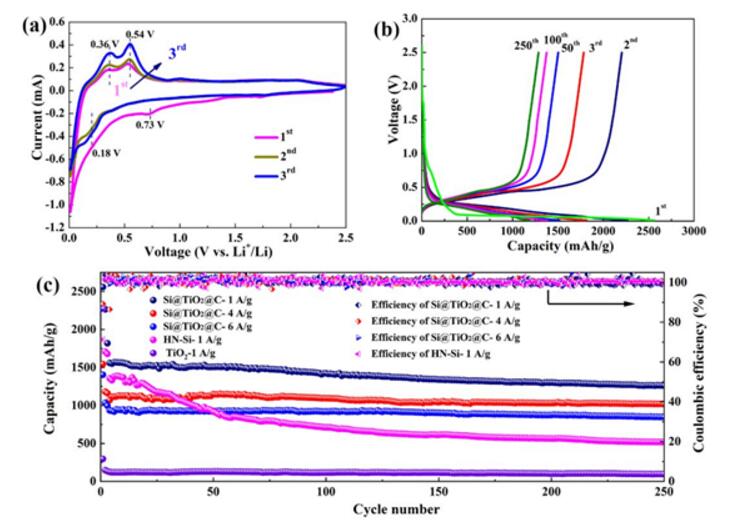

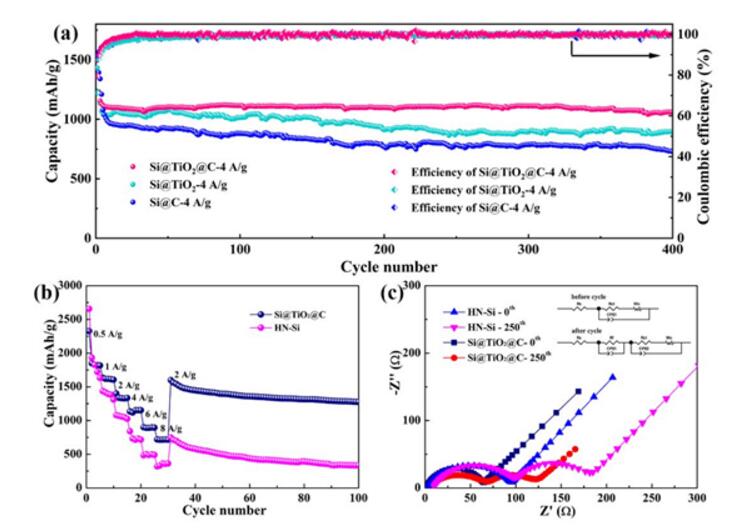

The results show that the double-stabilized hollow Si@TiO2@C nanosphere anode material synthesized by magnesium thermal reduction method and sol-gel method is the first time at a current density of 0.2A/g and an operating voltage of 0.01-2.5V. The specific discharge capacity was 2557.1 mAh/g, and the coulombic efficiency was 86.06%. At a current density of 1 A/g, the reversible specific capacity of the Si@TiO2@C anode material after 250 cycles is still 1270.3 mAh/g. The uncoated HN-Si anode material has a first discharge specific capacity of 2264 mAh/g and a Coulomb efficiency of only 67.3%.

This double-layer cladding-hollow structure design can shorten the transmission path of Li+ and electrons. The rich pore structure can also promote the full wetting of the electrolyte and improve its rate performance. At the same time, the uniform TiO2 shell and C layer greatly improve Si. @TiO2@C Anode material structural stability and electrical conductivity.

Figure 3 Characterization of electrochemical properties of Si@TiO2@C anode material

Figure 4 Schematic diagram of Si@TiO2@C(a) working device, (b) structural change of charge and discharge under TEM, and (c) schematic diagram of lithiation (delithiation)

Figure 5 Cycle performance, rate performance and impedance analysis

In summary, the design of the bistable cavity structure in this study can promote the further research and development of silicon-based anode materials, and also provide reference for the study of anode materials with serious volume expansion and poor conductivity.

References:

LuB, MaB, DengX, etal. Dual Stabilized Architecture of Hollow Si@TiO2@CNanospheres as Anode of High-Performance Li-IonBattery [J]. Chemical Engineering Journal, 2018.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China