Home > News

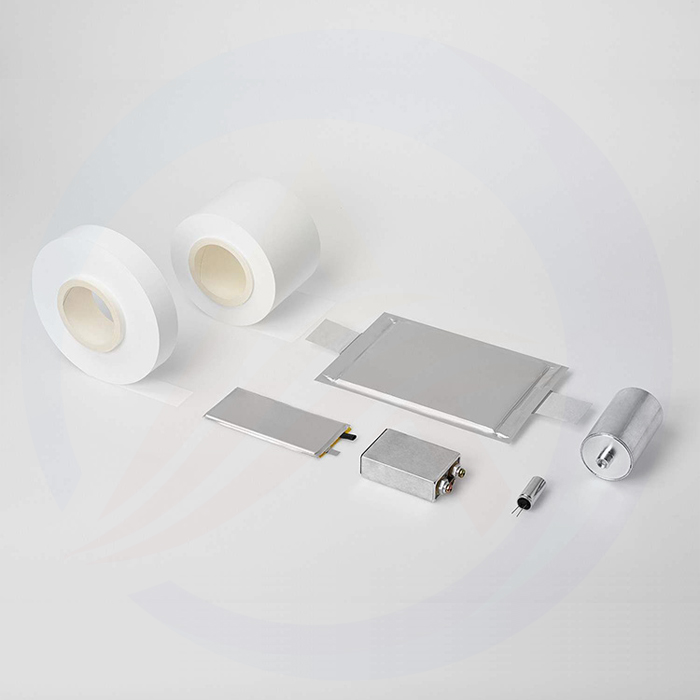

In lithium-ion batteries, the battery separator, also known as the separator, is a critical component located between the positive and negative electrodes. It acts as an insulating and permeable barrier that prevents direct contact between the electrodes while allowing the transport of lithium ions.

The separator plays several important roles in the performance of lithium-ion batteries:

1. Ion Transport:

The primary function of the separator is to allow the flow of lithium ions between the electrodes. It should provide low resistance to ion diffusion to facilitate efficient charge and discharge processes.

2. Electrolyte Permeability:

The separator needs to have good electrolyte wetting properties and high electrolyte permeability. This allows for the uniform distribution of the electrolyte throughout the battery and enables efficient ion transport.

3. Mechanical Stability:

The separator should possess sufficient mechanical strength to withstand the expansion and contraction of the electrodes during charging and discharging. It helps prevent the internal short circuit of the battery and maintains the structural integrity of the cell.

4. Thermal Stability:

The separator must have good thermal stability to withstand the operating temperatures of the battery. It should not shrink, deform, or melt at high temperatures, ensuring long-term safety and reliability.

5. Porosity:

The separator should have an appropriate level of porosity to allow the free flow of ions and facilitate efficient electrochemical reactions. Optimal porosity ensures a high energy density and good power performance in the battery.

Different characteristics of separators, such as thickness, pore size distribution, material composition, and surface morphology, can significantly impact the performance of lithium-ion batteries. Optimizing these characteristics helps to enhance the battery's energy efficiency, power density, cycling stability, and safety. Researchers focus on improving the design and properties of separators to advance the performance of lithium-ion batteries and meet the growing demands of various applications such as electric vehicles and portable electronics.

What are the effects of different characteristics of separators on the performance of lithium-ion batteries?

1. Porosity:

The porosity of the separator affects the battery's ability to transport lithium ions. A higher porosity allows for better ion flow, enhancing the battery's power and energy capabilities. However, excessively high porosity can lead to reduced mechanical strength and increased internal resistance.

2. Thickness:

The thickness of the separator affects the mechanical stability and safety of the battery. Thicker separators provide better physical protection, minimizing the risk of electrode piercing and short circuits. However, thicker separators also increase the internal resistance, reducing the battery's power output.

3. Puncture resistance:

separators with high puncture resistance protect the battery from mechanical damage during handling, assembly, and operation. They help minimize the risk of internal short circuits caused by electrode penetration, which could result in thermal runaway and safety hazards.

4. Electrolyte wettability:

separators need to be wetted by the battery's electrolyte to facilitate the transport of lithium ions. If the separator has poor wetting characteristics, it can limit the availability of the electrolyte and decrease ion conductivity, leading to reduced battery performance.

5. Thermal stability:

The separator should possess good thermal stability to withstand the high operating temperatures of lithium-ion batteries. If the separator degrades or shrinks at elevated temperatures, it can lead to internal short circuits and thermal instability, compromising the battery's safety.

6. Chemical compatibility:

separators should be chemically compatible with the electrolyte and other battery components to ensure long-term stability and prevent degradation. Any chemical reactions between the separator and the electrolyte could lead to capacity loss, increased internal resistance, and reduced cycle life.

Optimizing separator characteristics is crucial for maximizing the performance, energy density, safety, and cycle life of lithium-ion batteries. Battery manufacturers continuously work on developing and improving separator materials and designs to achieve optimal performance and safety parameters for specific battery applications.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China