Home > Ball Mill

Brief introduction

Planetary ball mill is a necessary device for mixing,fine grinding,small samples prepared,dispersion of nanometer, R&D of new product and small batch production for high tech materials.

The equipment with small volume,comprehensive function,high efficiency,low noise which is the ideal device of obtaining micro-particle research samples used for research and development institute,collages and universities,entire laboratory.

The samples could be ground under vacuum state with using the vacuum ball mill jars.

It is widely used in geology,mineral,metallurgy,electronic,building material,ceramic,

chemical,light industry,medicine,beauty,environment production,tea and so on.

According to the processing requirement to set the rotation speed and alternate time of forward and reversal rotation and set the total grinding time.

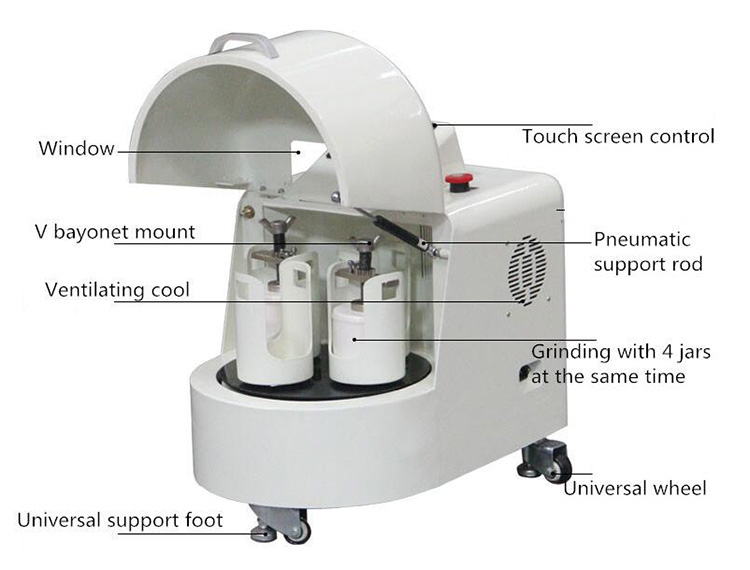

Feature of planetary ball mill

1.Unique gear structure, grease lubrication, low noise, good performance, no liquid oil lubrication form that may cause oil leakage due to prolonged use.

2.PLC frequency conversion control:the inverter has the protection of undervoltage and overcurrent, and has the memory after the power off, so it can protect the motor.

3. With own design for precision gear drive instead of original belt drive,such as belt easy to slip and unstable speed.

4.Suitable for dry/wet/vacuum/protective atmosphere/low temperature/high temperature mill.

5.Ensures the Homogeneity and repeat-ability of the experiment.

6.It can solute the problems for the deposition and sticking of some materials and four samples could be obtained with different sizes in one experiment.

7.Low center of gravity, stable performance, compact structure, convenient operation, safe and reliable, low noise, no pollution, low loss.

8.The device is equipped with a safety switch, which can avoid the equipment running after opening the safety cover, and avoid a safety accident;

9.When carrying, there are universal wheels to push and run;When operating, there are universal supporting feet for stable.

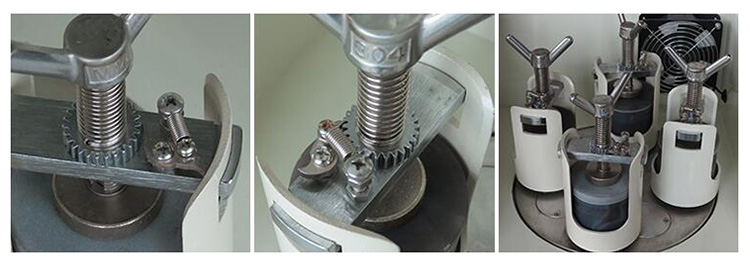

10.V bayonet mount with automatic gear lock, easy to install and disassemble, easy to loosen, safe and reliable, simple and easy to use, delicate design and beautiful shape.

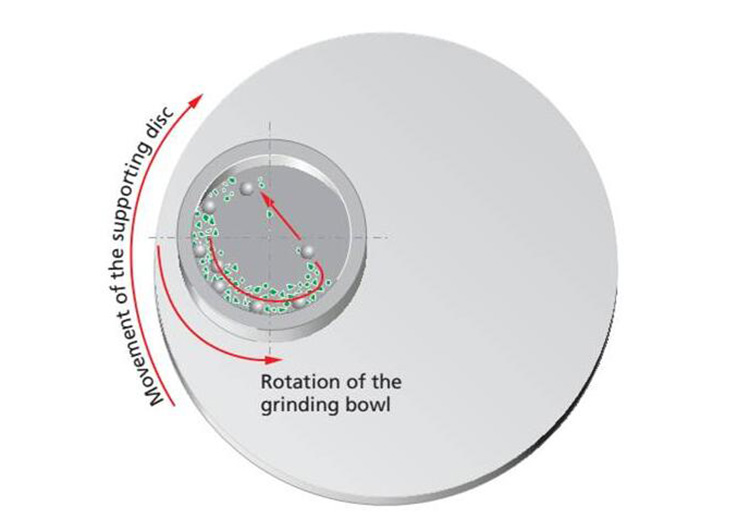

Working principle:

Quiet planetary Ball Mill has four ball grinding tanks installed on one turntable.When the turntable rotates, the tank axis makes planetary movements,The balls and samples inside the jars are impacted strongly in high speed movement, and samples are eventually ground into powder. The ball mill can use for dry and wet grinding and also can mix products of different granularity and materials.

Working mode: Two or four ball milling jars working at the same time and the maximum sample loading amount: Volume of ball milling jar 2/3, feeding granularity:soil material≤10mm other material≤3mm discharge granularity: the minimum can up to 0.1um (i.e. 1.0 *10mm-4).

Model | Planetary Ball Mill AOT-XQM-0.4A |

Source voltage | AC110V/220V 50/60HZ |

Total power | 0.45KW |

Warranty | One year limited with lifetime support |

Voice processing | Quiet processing technology |

Ball milling tank volume | 100ml x4, 100ml x 2 (or 50ml x 4, 50ml x 2 ) |

Milling tank materials | Metal material: 304 stainless steel, cemented carbide (YG8) |

Nonmetallic material : ceramic/corundum/alumina, zirconia, agate | |

High polymer material : nylon, polyurethane, ptfe | |

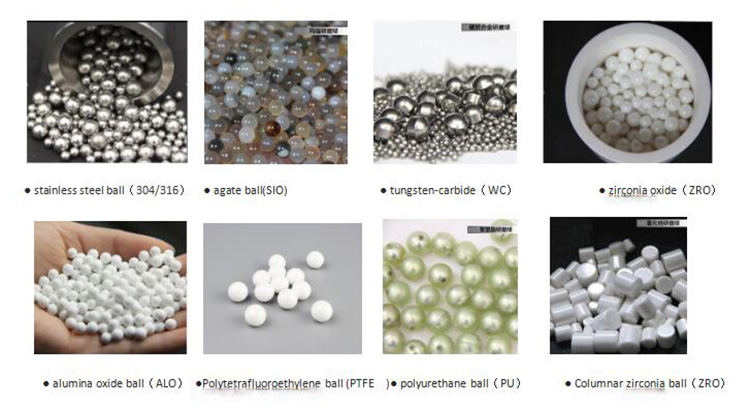

Ball mill medium | Stainless steel, ceramic/corundum/alumina, zirconia, agate, cemented carbide |

Max charge of tank | No more 1/3 of the volume |

Filling materials size | Crispy material is less than 10 mm, other less than 3 mm |

Single tank fill quantity | 100ml tank with 33ml material |

Output material size | Min 0.1um |

Grinding mode | Dry/wet/high-energy alloying grinding/vacuum/cryogenic grinding, last two model need customized |

Max continuous working time | 72 hours |

Rotation speed | 0-900r/min |

Revolution speed | 0-450r/min |

Speed ratio | 2:1 |

Dimension | 600*400*500mm |

Weight | 60kg |

Material of milling jar

Material of ball

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China