Home > Ball Mill

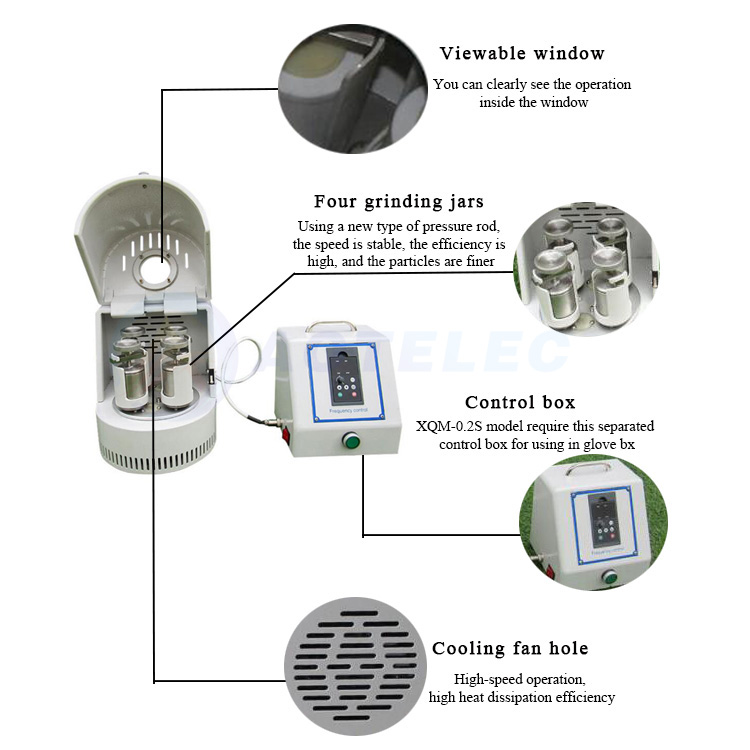

DESCRIPTION:

1 Planetary ball mill is necessary equipment for mixing, fine grinding, sample preparing, nano-materials dispersing, new product developing and preparing small volume high-tech material production.

2 the Planetary ball mill is small, full-featured, high efficiency and low noise which is the ideal equipment for scientific research units, institutions of higher learning, corporate laboratories to obtain micro particle research samples. (Four samples for each experiment).

3 It can be equipped with vacuum ball mill; the sample can be ground under vacuum. It is widely used in geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty, environmental protection and other departments.

4 It can set the speed, forward and reverse rotation time, and the total grinding time according to process requirement.

5 the small volume can be worked in glove box.

Application of Planetary Ball Mill

1.Geology and Mineralogy: rock, gravel, sand, minerals

2.Ceramics: porcelain, sintered ceramics, clay, fireclay

3.Chemistry: pesticides, fertilisers, salts, inorganic and organic materials

4.Biology: plants, leaves, freeze-dried samples

5.Pharmaceuticals: ophthalmological agents, gels, creams, extracts, drugs, pastes, dragees, tablets

6.Metallurgy: ores, sinters

7.Material technology: pigments, precious materials, new materials, alloys, mechanical alloying and activating

8.Analysis preparation: spectroscopy, X-ray fluorescence, X-ray structure analysis, chromatography

Technical parameter:

Model | AOT-XQM-0.2 |

Grinding tank volume (L) | 50ml*4 |

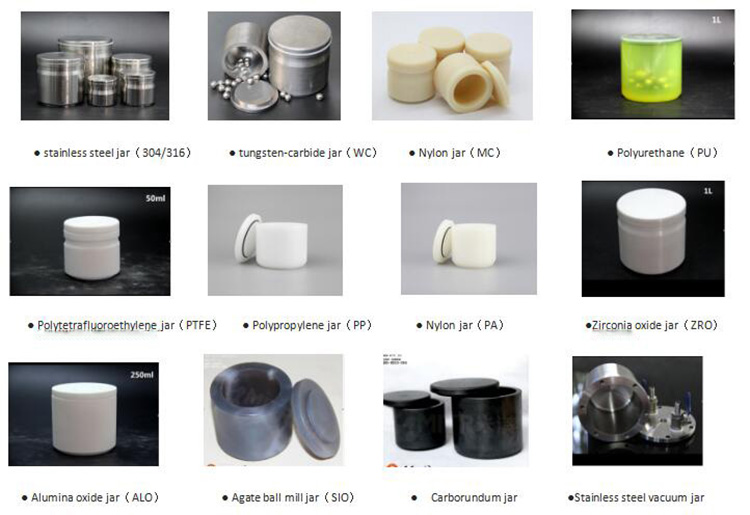

Grinding tank material | According to requirements |

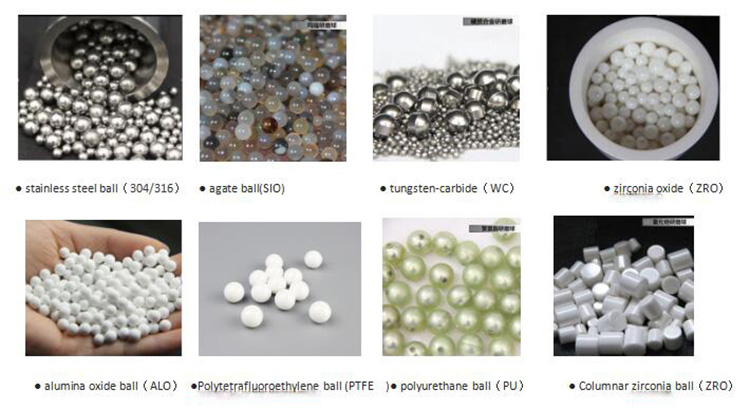

Grinding media | According to requirements |

Maximum loading per tank | Material and grinding medium does not exceed two-thirds of the volume |

Feeding material size | Soil material ≤ 10 mm, other materials ≤ 3 mm |

Discharge material size | Min 0.1um |

Rotating speed | Revolution 60-580r / min, Rotation 120-1160 r / min |

Speed ratio (revolution: rotation) | 1:2 |

Speed mode | Frequency, programmable stepless speed regulation, manual, automatic timing forward and reverse |

Transfer method | Gear drive |

Working Voltage | 220V |

Motor power and variable frequency power | 0.15Kw |

Way of working | Two or four cans work at the same time |

Maximum continuous operating time | 72hours |

Programmable control (electronic monitoring) | Ball mill using high-tech microcomputer chip control, can be set to forward and reverse alternately run(0-999min) and forward, pause, reverse, pause, forward (0-999min) alternate operation according to the procedure. Particularly suitable for cooling or intermittent operation. |

Dimension | 250mm*425mm*280mm / 220mm*410mm*270mm(XQM-0.2S) |

Weight | About 28KG |

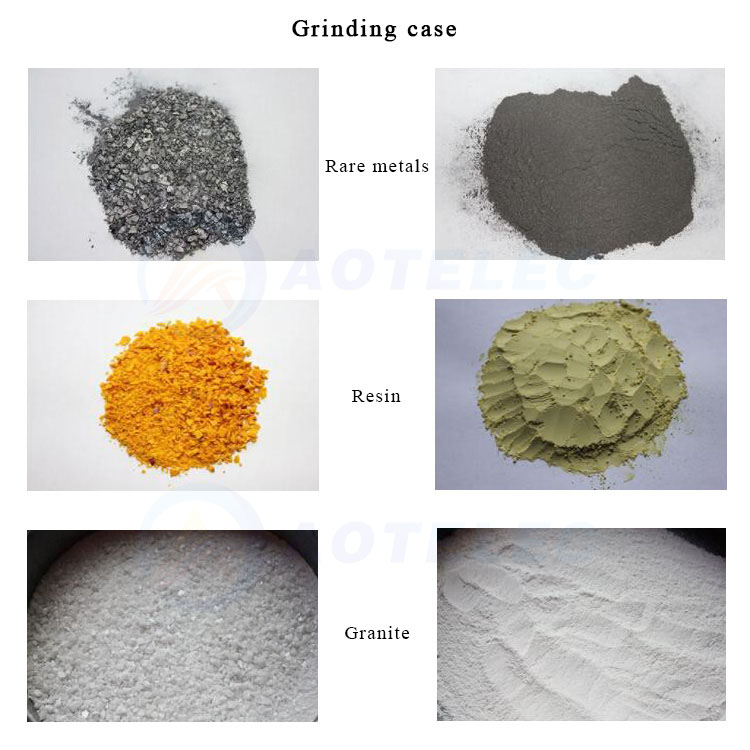

Grinding Case of Ball Mill

Optional Balls and Jars

Exhibition

Exhibition

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China