Home > Technological Innovation

Semi-solid battery technology will be an emerging standard for lithium-ion battery manufacturing.

Compared to existing lithium batteries, the semi-solid lithium battery can reduce material costs by about 40% and shorten the manufacturing process by a third. Compared with all-solid-state batteries, it has fewer technical problems, achieves high security and high density, now people pay more attention to it.

For this new type of battery, uses a completely new battery slurry composition, it consisting of an electrode and a collector (usually it is a metal sheet).

The existing slurry include:

(1) Active substances (absorbing and discharging lithium ions, which help to store energy),

(2) an adhesive that makes the slurry easier to adhere to the metal foil,(3) A solvent which makes the slurry easier to use.

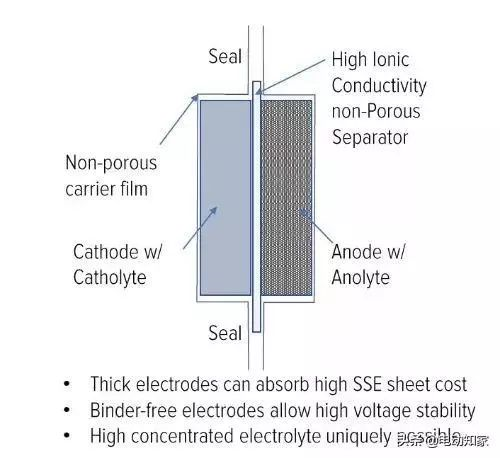

On the other hand, new batteries do not require binders and solvents. The existing production process requires that the slurry obtained by liquefying the binder or solvent is applied to the metal foil, and then dried, the volume of the slurry is reduced, and the slurry cannot be thickly coated. The new lithium-ion battery eliminates the drying process by not using a binder to make the slurry thicker.

Improve safety and reliability through improved design

New battery characteristics

(1) Design to improve safety and reliability;

(2) It is possible to increase the capacity density to a level that cannot be achieved by existing batteries.

(3) It can recover rare materials at low cost without decomposing them.

In the previous production, the metal powder used to constitute the battery generates metal powder entering the battery during cutting and welding, or short-circuit between the positive and negative electrodes due to electrode displacement, causing a fire accident. But this new battery does not require cutting metal because it uses metal foil that has been previously processed. If a small unit is short-circuited, it will be insulated by the bag material and will not affect other cells.

More material choices may achieve a capacity density of 500Wh/kg

New batteries have the potential to increase capacity density because they enable the selection of electrolytes and active materials from more options than existing batteries.

In terms of the electrolyte, a suitable electrolyte can be selected for each of the active materials of the positive electrode and the negative electrode by placing a solid electrolyte between the positive electrode and the negative electrode.

On the other hand, for example, for a new battery, an ether-based material suitable only for the negative electrode and a fluorine-based material suitable only for the positive electrode can be used.

Lossless material recovery

The material of the new battery is easy to recycle. Since the slurry does not contain a binder, the slurry can be easily separated from the metal foil and recovered as a raw material used in the production process.

Welcome to visit us during this exhibition.

Contact: Ms.Lika (Sales)

Email: sales@aotbattery.com

Phone: 0086-19906035385

Skype:sales@aotbattery.com

Web: www.aotbattery.com

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China