Home > Technological Innovation

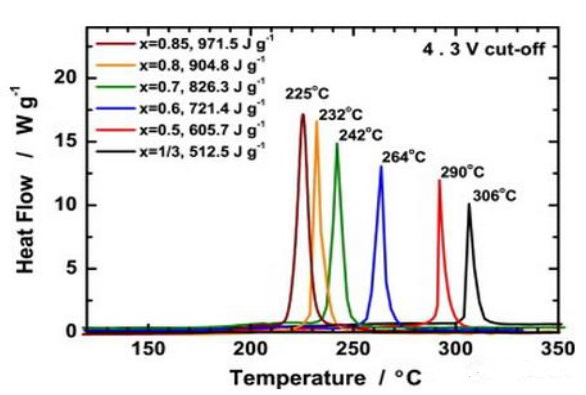

As the NCM energy density continues to increase, the thermal stability of the material will become worse and worse. The graph below shows that the decomposition temperature of the material gradually decreases as the Ni content increases.

The safety of NCM high-nickel materials can be solved step by step through material modification optimization, surface coating and electrolyte adjustment.

1 Coating of ceramic alumina, Al2O3 can consume HF in the battery system by forming Al-O-F and Al-F layers, and the charging voltage can be increased to 4.5V.

2 Control the Ni content in a reasonable range (811 is of course more unstable than 622).

3 Performing appropriate doping coatings on other metal elements (Al, Mg, Ti, Zr) can improve the structural stability, thermal stability and cycle stability of the material.

4 The use of additives to optimize the electrolyte can effectively promote the formation of high-quality surface film on the surface of the electrode material, while inhibiting the oxidative decomposition of the electrolyte.

5 High-boiling point and flash point flame retardant additives are added to the electrolyte. Commonly, there are organic phosphorus and fluorophosphate series.

6 The choice of ceramic separator, to improve the thickness of the membrane substrate and coating, the use of a new type of non-woven fabric with low temperature shrinkage.

AOT ELECTRONIC TECHNOLOGY CO.,LTD which has 10 years experience in LITHIUM ION BATTERY field. We provide full kinds of battery equipment and material, the lab research line is available according to the requirements of customer.

Advantage of Technology, Advantage of Team!

Contact: Ms.Lika (Sales)

Email: sales@aotbattery.com

Phone: 0086 182 5072 9722

Skype:sales@aotbattery.com

Web: www.aotbattery.com

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China