Home > Technological Innovation

The theoretical specific capacity of lithium iron phosphate cathode material is 170mA/g, and the voltage platform is 3.2V. It has the advantages of rich raw material source, non-toxicity, environmental friendliness, high safety, high specific capacity, stable cycle performance and low price. It is considered to be an ideal cathode material for lithium ion power batteries. However, due to its own structural limitations, the lithium ion battery with LiFePO4 as the positive electrode material has poor conductivity, slow diffusion rate of lithium ions, and poor discharge performance under low temperature conditions, which restricts the large-scale industrial production of LiFePO4 cathode materials.

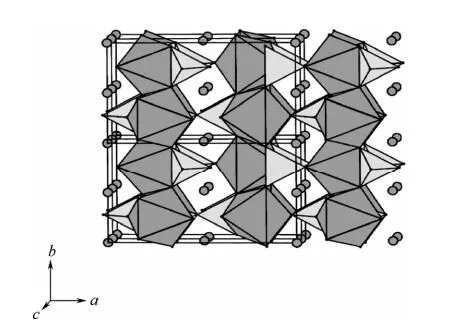

Basic structure of lithium iron phosphate

The lithium iron phosphate cathode material has an orthogonal olivine structure, a pnma space group, as shown in FIG. The LiFePO4 structure is chain-like in the c-axis direction, and one PO4 tetrahedron is co-edge with one FeO6 octahedron and two LiO6 octahedrons, thereby forming a three-dimensional network structure.

Structurally, the PO4 tetrahedron is located between the FeO6 layers, which hinders the diffusion of lithium ions to some extent. In addition, the FeO6 octahedron of the common apex has a relatively low electron conductivity. This allows lithium iron phosphate to be charged and discharged only at a small discharge rate, and under large-rate discharge conditions, the internal lithium ions are too late to move out, and the electrochemical polarization is large.

Figure 1 Schematic diagram of LiFePO4 crystal structure

Modification of lithium iron phosphate material

1. Doping method

Mainly refers to the doping of some conductive metal ions in the cation position in the lithium iron phosphate lattice, changing the size of the crystal grains, causing lattice defects of the material, thereby improving the conductivity of electrons in the grains and the diffusion of lithium ions. The rate, in turn, achieves the goal of improving the properties of the LiFePO4 material. At present, the doped metal ions mainly include Ti4+, Co2+, Zn2+, Mn2+, La2+, V3+, Mg2+ and the like. The amount of doping is important, and excessive doping can cause changes in the internal structure of the material, which can change the material properties.

2. Carbon coating

(1) One is to add the carbon powder to the raw material according to a certain ratio, and after uniformly mixing, the reaction is carried out under a high-temperature reducing atmosphere;

(2) The other is to add an organic compound to the precursor of LiFePO4, react in a high-temperature reducing atmosphere, pyrolyze the organic substance to form carbon, and form a carbon coating on the surface while forming LiFePO4. Usually, the selected organic matter contains only three elements of carbon, hydrogen and oxygen to ensure that no other impurity atoms are mixed in.

3. Material nanocrystallization

It is the best method to increase the diffusion rate of lithium ions by preparing nano-sized particles and reducing the diffusion distance of lithium ions. At present, the method for reducing the particle size of LiFePO4 mainly includes mechanical ball milling, controlling calcination temperature, using ultra-fine conductive particles with high specific surface area as nucleation promoters, using homogeneous precursors during synthesis, and carbon coating to limit crystal growth.

Summary

At present, with the development of LiFePO4 industry, LiFePO4 modification technology is also developing continuously, and the modification method is not single. For various performance and structural defects of LiFePO4, various modification methods are combined, such as material nanocrystallization and carbon. A combination of coating and ion doping methods for modification studies can achieve a comprehensive electrochemical performance.

AOT ELECTRONIC TECHNOLOGY CO.,LTD which has 10 years experience in LITHIUM ION BATTERY field. We provide full kinds of battery equipment and material, the lab research line is available according to the requirements of customer.

Contact: Ms.Lika (Sales)

Email/Skype: sales@aotbattery.com

Phone / WhatsApp/ Wechat: 0086-15980808150

Web: www.aotbattery.com

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China