Home > Battery Production Line

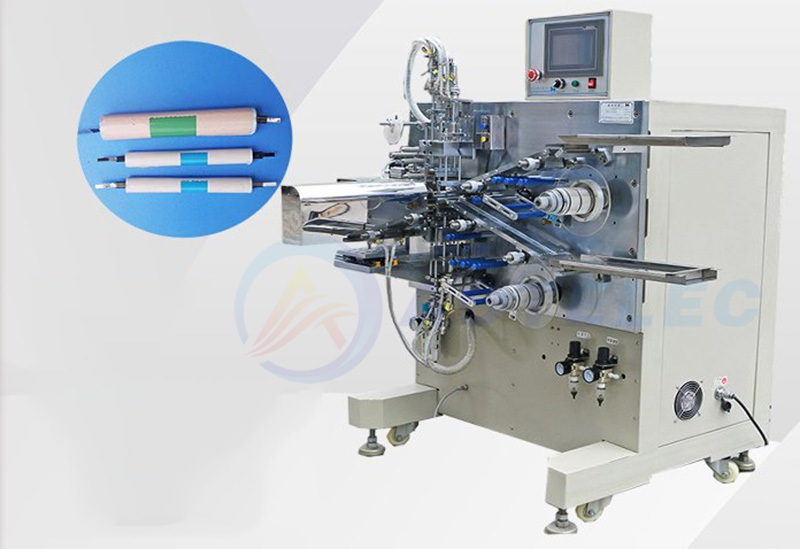

This machine is mainly applicable to the winding of cylindrical lithium-ion battery cells.

1) Artificial monolithic upper electrode piece, automatic winding, automatic change of winding needle, automatic sticking termination tape and cutting, automatic unloading

2) Separator continuous, separator tension can be adjusted according to need, tension adjustment range: 0.1N-10N, and keep constant.

3) The tension of the electrode piece can be controlled during the winding process.

4) The width of the electrode piece trough can be adjusted to fit different types of electrode pieces widths, with high dimensional accuracy and wear-resisting, smooth surface.

5) This equipment adopts transverse sticking, the length and width of sticking can be adjusted greatly, it is very easy to ensure the appearance and size quality of the electric core.

6) The coil needle made of high-strength materials can be smoothly pulled out without affecting the neatness of the already rolled core, nor will it scratch the separator or cause the core to become spiral shaped

7) Roll needle diameter range: ¢2.5 --- ¢8.0, suitable for winding various specifications and models of cylindrical lithium-ion batteries such as 14500, 14430, 18650, 2665032650, etc

8) separator continuous feeding, PLC and precision potentiometer constant tension control, pressure sensor detection, the electric core winding process is uniform force.

9) Utilization rate: ≥98%

10) The yield rate of the wound battery core can reach 98%, and the error of electrode ear center distance: ≤ ± 0.5mm

Technical indicators:

Product Name | 18650 Semi-automatic Winding Machine |

Winding accuracy | a. Overlapping accuracy of positive and negative electrode plates: ± 0.3mm (refer to the range of Aluminum Foil) b. Repetitive deviation accuracy of bipolar ear: (0.5-1mm) c. Diaphragm alignment accuracy: ≤ ± 0.2mm |

Utilization rate | ≥98% |

Yield rate | ≥98% |

Power supply | 220v50Hz |

Power | about 1Kw |

Air pressure | 0.4-0.6MPa |

Paint color | computer white |

Machine dimensions | 1200mm × 1260mm × 1650mm (L × W × H) |

Speed | ≥ 8 ~ 12 pieces / min (related to the length of the electrode piece and personnel proficiency) |

V. Equipment configuration

specifications | Remarks | ||

Basic specifications | Input power supply | AC220V, 1.5KVA, 50HZ | |

Compressed air source | 0.4~0.6Mpa | ||

Production capacity of equipment | 8~12 PCS/min | Taking the electrode length of 700mm as an example | |

Equipment weight | About 800kg | ||

Equipment size | 1200mm×1260mm×1650mm (L×W×H) | ||

Needle specifications | ¢2.8-- ¢8.0 | Choose either one | |

Institutional specifications | Rack and mounting plate | 1 set | |

Needle rolling device | 1 set | ||

electrode supply device | 2 sets | ||

Diaphragm supply device | 2 sets | ||

Adhesive device | 1 set | ||

Control system specifications | Central controller P L C | Delta | |

Touch screen | MCGS | ||

Winding servo motor | ESTUN | ||

Pneumatic components | Air TAC JYC | ||

alarm system | Fault stop | ||

Fault indication | Program built-in | One click reset | |

attachment | Operation manual | 1 set of operation manual | |

Company Profile

Xiamen AOT battery equipment Technology Co LTD was set up as a manufacturer in 2006. We have total manufacturing facilities of around 4, 000 square meters and more than 65 staff. Owning a group of experienced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy. AOT Battery has been focused on product development and operations of lithium battery and its surrounding, we supply full kinds of lithium-ion battery equipment, lab battery raw materials and lithium-ion battery research and development technology.

Exhibition

AOT Lithium Battery Equipment exhibition provides exhibitors and visitors with a comprehensive platform for display, exchange, cooperation and trade. By participating in the exhibition, enterprises can understand the industry dynamics, expand market channels, enhance brand image and promote technological innovation and industrial upgrading.

Certificate

Cooperative

FAQ

Q1:How long do you need to prepare my goods?

A: 3-5 days for battery materials. 5-25 days for equipment (based on different model and quantities).

Q2:Can we have our logo or company name to be printed on products or package?

A: Sure. your logo could be printed on your products by hot stamping, printing, embossing, UV coating, silk-screen printing or sticker. In order to explore the market better and provide more convenient services to global customers, we sincerely invite overseas agent to create bright future together.

Q3:How can I install and operate the machine by myself?

A: Our system R&D based on integrated development view. when you get the machine, just need to connect it with the electrical power, then machine can be working. because the English software were installed in this machine. what you need to do is only learning the software usage, and the complete English user manual will be coning to you with the machine.

Q4:How to get technical support after purchasing?

A: Our factory provide online technical support in English , you can easy catch us online by Skype, Wechat, and Email, if you need any remote assistant support, then we will support you though Team Viewer.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China