Home > Pouch Cell Lab Equipment

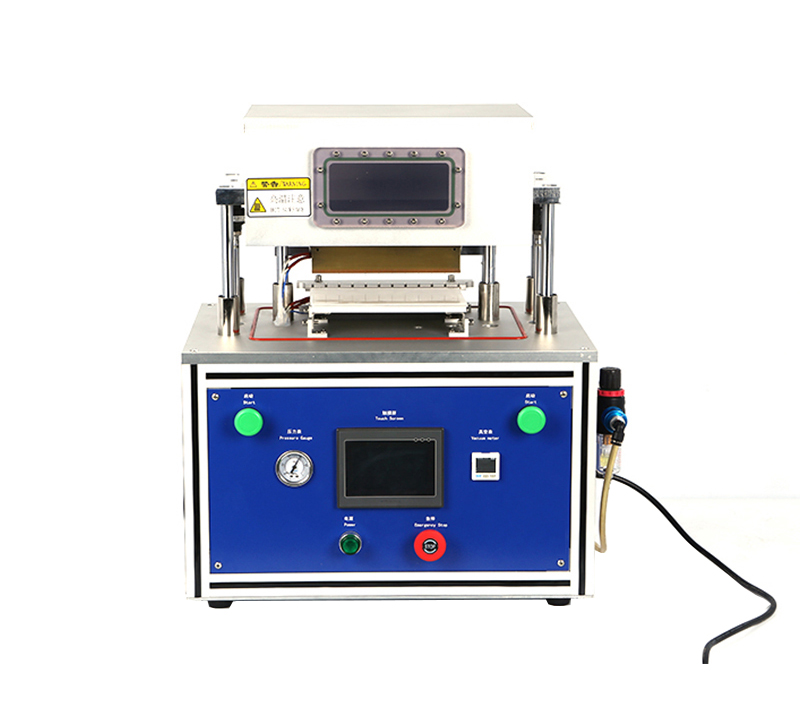

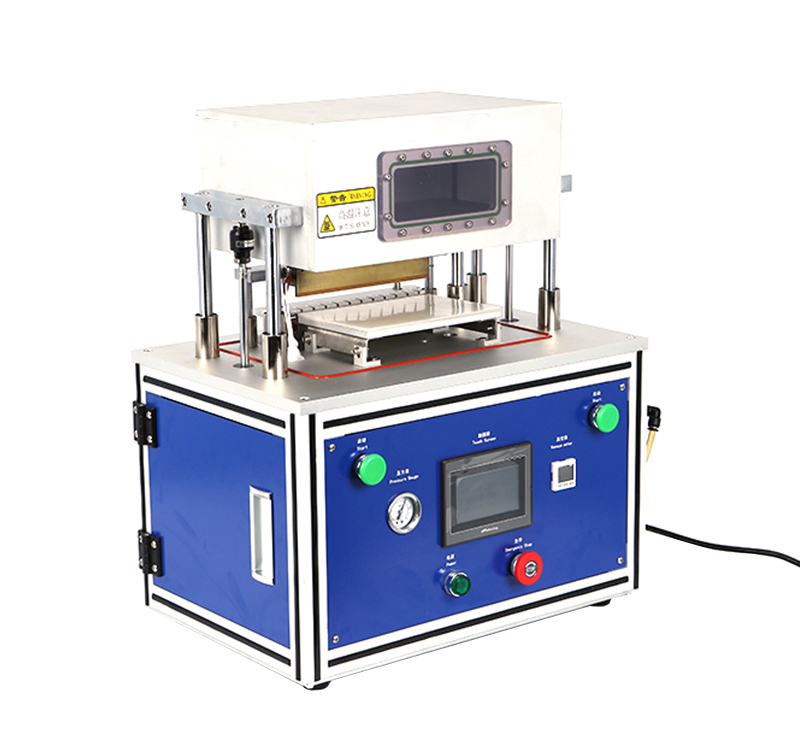

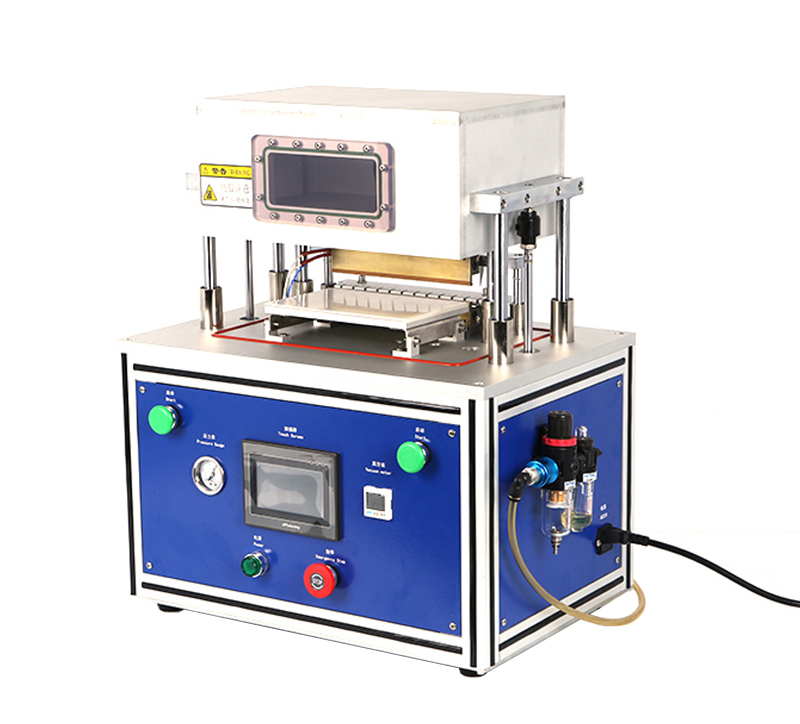

Lithium Batteries Equipment Secondary Vacuum Sealing Machine for Polymer Cell after Electrolyte Filling

This equipment is used for lithium pouch cell vacuumizing and final heat sealing after filling & electrolyte diffusion process.

Features :

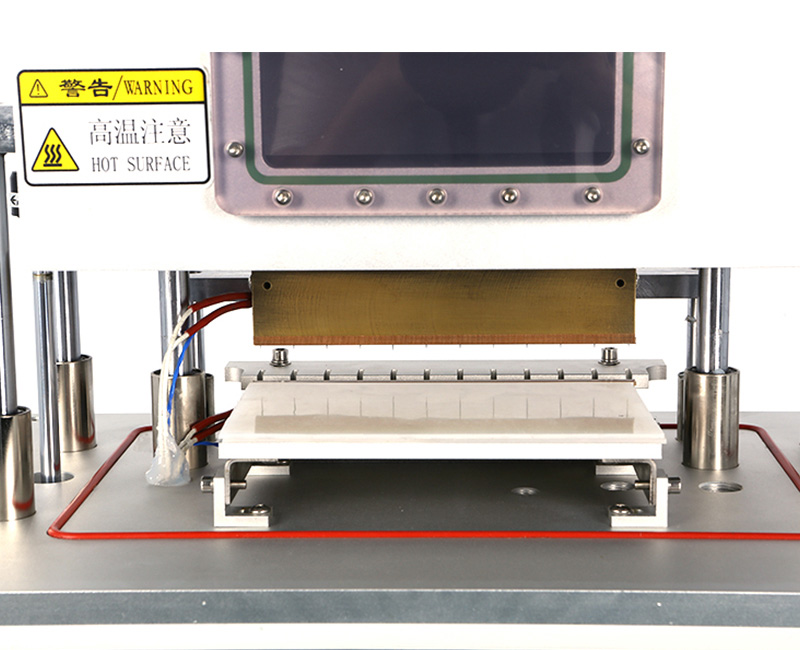

1. The sealing head is made of copper material so that the heat transfer effect is good to save

power consumption , improve work efficiency and more energy-saving than

other similar products.

2. Pressure of upper and lower sealing heads can be regulated by pressure regulating valve to meet different technological parameter demands.

3. The lower and upper sealing heads are driven by cylinder through two linear-guide bushes that makes them move up and down flexibly and ensures the parallelism demand after sealing.

4. It’s designed with puncture function.

5. The lid of chamber is driven by cylinder through linear-guide bushes that makes them flexibly and ensures the good sealing.

6. It can be used for different battery, easy adjustment.

7. Simple operation, nice appearance, small size, light weight

POUCH CELL LAB EQUIPMENT Vacuum Heat Sealing Machine AOT-VFS-200 | |

Chamber material | The chamber is made from Aluminum alloy, non-corrosive |

Vacuum degree | ≤-95Kpa (Buyer prepare vacuum pump) |

Sealing head temp | Room temp ~250℃. it’s adjustable |

Temp accuracy | ±1.5℃ |

Heat sealing pressure | 0~7Kg/cm2 (adjustable) |

Heat sealing time | 0~99s adjustable |

Sealing width | 5mm |

Max sealing size | 200mm |

Sealing head flatness | Test by triple carbon carbonless paper, set the head air pressure at 0.6MPa, the temperature at 200 degrees, the extrusion of the seal evenly |

Air compressor working speed | ≥180 tims/h |

Power | 300W heating pipe, the power consumption around 0.6KW when heating . |

Power supply | 220V/50Hz |

Power: 50W | 50W |

Compressed air | 0.5~0.7Mpa |

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China