Home > News

In the battery manufacturing industry, the battery sealer is undoubtedly an indispensable key equipment. It is not only related to the safety performance of the battery, but also directly affects the service life and overall performance of the battery. Today, we'll take a closer look at this amazing machine and see how it plays an important role in the battery manufacturing process.

一、the basic overview of the battery sealing machine

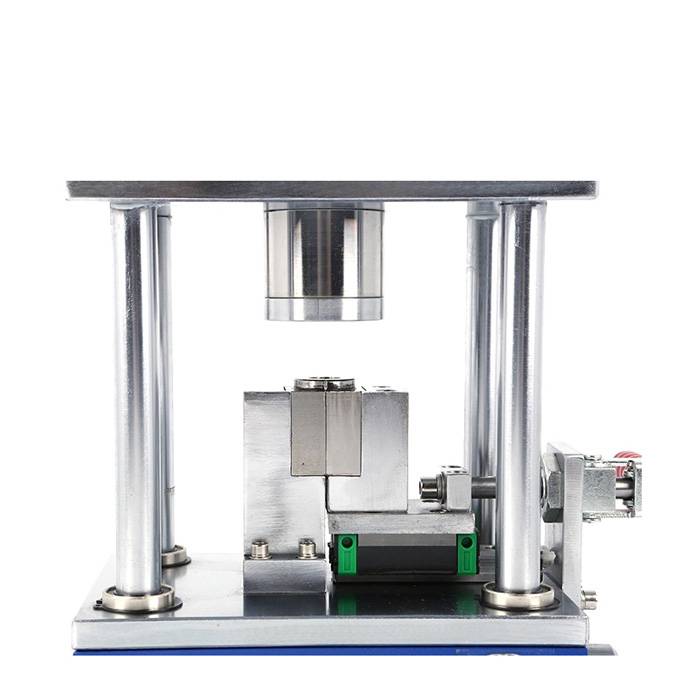

Battery sealer, as the name suggests, is a special device used to seal the battery. In the battery production process, sealing is an extremely important step, because it is directly related to the electrolyte inside the battery will not leak, to ensure the safety of the battery. Through high temperature, high pressure or other means, the positive and negative electrodes of the battery are closely connected with the housing to form a sealed whole.

二、 the technical characteristics of the battery sealing machine

High efficiency: The battery sealing machine adopts advanced automatic control system, which can achieve fast and accurate sealing operation, greatly improving production efficiency.

Accuracy: The high precision of the sealing machine can ensure that each sealing meets the predetermined standards and requirements, ensuring the quality and stability of the battery.

Safety: During the sealing process, the sealing machine monitors the temperature, pressure and other parameters in real time to ensure the safety and reliability of the operation process.

Adaptability: The battery sealer is suitable for various types of battery production, such as dry batteries, lithium batteries, nickel metal hydride batteries, etc., and has a wide range of applicability.

三、 the working principle of the battery sealing machine

The working principle of the battery sealer mainly depends on high temperature, high pressure or other physical effects. Taking the heat sealing method as an example, when the positive and negative electrodes of the battery and the shell are placed on the workbench of the sealing machine, the sealing machine will heat the sealing part through the heating element to make it reach a certain temperature. Then, by applying a certain pressure, the positive and negative electrodes are closely fitted with the shell to form a sealed structure. During the cooling process, the sealing part will gradually solidify, forming a strong sealing layer.

四、 battery sealing machine operation and maintenance

Operation: The operation of the battery sealer is relatively simple, but it needs to be carried out in strict accordance with the operating procedures. During operation, pay attention to safety precautions, such as wearing protective glasses and gloves. At the same time, the sealing machine should be inspected and maintained regularly to ensure its normal operation.

Maintenance: The maintenance of the battery sealer includes daily cleaning, regular inspection, replacement of wearing parts, etc. In daily use, attention should be paid to keeping the sealing machine clean and dry to avoid dust and impurities entering the machine. Regularly check whether the various parts of the sealing machine are working normally, and if abnormal conditions are found, they should be handled in time. At the same time, it is necessary to regularly replace the wearing parts, such as heating elements, sealing rings, etc., to ensure the performance and stability of the sealing machine.

五、the importance of battery sealing machine in battery manufacturing

The battery sealer plays a crucial role in the battery manufacturing process. It can not only ensure the safety of the battery, but also improve the service life and overall performance of the battery. Specifically, the precision operation and strict standards of the sealer ensure the tightness of the battery and prevent the leakage of the electrolyte, thereby reducing the safety risk of the battery during use. At the same time, the good sealing effect can also improve the service life and performance stability of the battery, so that it can maintain stable performance output in a variety of environments.

六、 the development trend of battery sealing machine

With the continuous progress of science and technology and the continuous development of battery manufacturing technology, battery sealing machines are also constantly updated. The future battery sealer will pay more attention to automation, intelligence and environmental protection. The introduction of automation and intelligence will further improve production efficiency and quality stability, while the improvement of environmental protection will reduce energy consumption and pollution emissions in the production process, contributing to the sustainable development of the battery manufacturing industry.

Vii. Conclusion

As an important equipment in the battery manufacturing process, the performance and stability of the battery sealer are directly related to the quality and safety of the battery. Through in-depth understanding of the working principle, operation and maintenance of the battery sealer, as well as its importance in battery manufacturing, we can better understand the value and role of this amazing machine. In the future development, we look forward to continuous innovation and progress of the battery sealing machine, which will inject new impetus into the development of the battery manufacturing industry.

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China