Home > Battery Pack Assembly Line

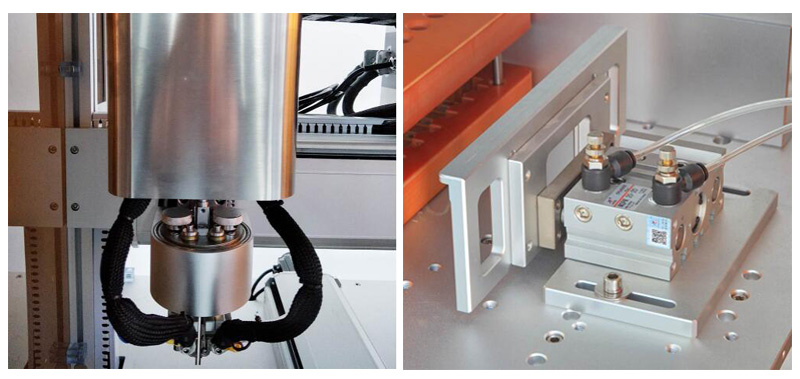

Semi-Automatic Single Side Spot Welder Machine with Rotary Welding Head

AOT-DH-10000R Single-side automatic spot welding machine Characteristic:

1.Using Motion Controller, Support arrays and non-arrays Rapid Programming for Simple Operation of Battery Pack.

2.Self-contained current welding alarm,Effective solution rosin joint.

3.Welding head rotation Effective solution Sticking Needle Problem of Nickel Plate and Pure Nickel Plate for Battery.

4.Welding needle compensation function Water-cooled heat dissipation system,Reducing the loss of welding needles.

Equipment configuration

Spare parts | Brand |

Servo motor | Panasonic / Fuji |

Stepper motor | Reiser / Panasonic |

Solenoid valve | SMC Airtac |

Support base | NSK |

Linear guide rail | TouchWin |

Power Supply | MingWei |

Inductorium | OMRON、SUNX |

Button | Goncon |

Electric relay | OMRON |

| Indicator | Goncon |

Specifications:

Model | Semi-Automatic Spot Welding Machine AOT-DH-10000R |

Power Box | 8000A (Customizable) |

Welding power source | Three-phase 380V + 10% / 50Hz + 10%; power < 1000W |

Welding power consumption | 1500W |

Platform input voltage | 220V 50HZ, platform power consumption <800W |

Overall size | 1100mm(L)*1000mm(W)*1500mm(H) |

Weight of equipment | 360Kg |

Welding head inlet spring pressure regulation | 1.0-5.0 KG |

Welding nickelstrip thickness | 0.12mm-0.3mm |

Suitablenickel sheet with salient point | 0.2-0.3 steel nickelcoated steel/pure nickel |

Positive and negative current switching speed | 10-50ms |

Spec for positive and negative current switching | 2-4 polarity switching options |

Setting of upper and lower limits of welding current and output of waveform monitoring | |

Welding speed offlat welding | 0.7-0.8S 1800-2000pcs/h |

Welding speed of bump welding | 1.2-1.5S 1000-1500pcs/h |

Welding current upper and lower limit setting | Support |

X-axis Y-axis displacement accuracy | 0.05mm |

Weld Joint Import Spring Pressure Adjustment | 1.0-5.0 KG |

X-axis stroke | 560mm (customizable) |

Y-axis stroke | 340mm (customizable) |

Welding Module | Single Module and Multiple Modules Optional |

Suitable for cylindrical battery type | 18650 ,26650 ,32650 |

Array programming time | 1-2 minutes |

Special battery pack programming time | 2-3 minutes |

Welding head rotation angle | 0-180 degrees |

Driving mode | servo + imported precision linear screw + Guide |

Operating System | Embedded Motion Control System+ Man-Machine Screen |

Exhibition

Cerificate

Contact: Lika

Phone: +86-19906035385

Tel: 0086-592-7161550

Email: sales@aotbattery.com

Add: No.168, Zhaogang Road, Xiamen City, China